1. Non-contact continuous measurement does not require direct contact with the measured medium, so the type of medium being measured is almost unlimited. It can be widely used for measuring various liquid and solid levels and is not easily affected by the viscosity and density of the liquid. With temperature compensation function, it can be used in environments with large temperature differences, with high accuracy and strong adaptability.

2. Equipped with RS-485 communication interface and special echo processing method, effectively avoiding false echoes.

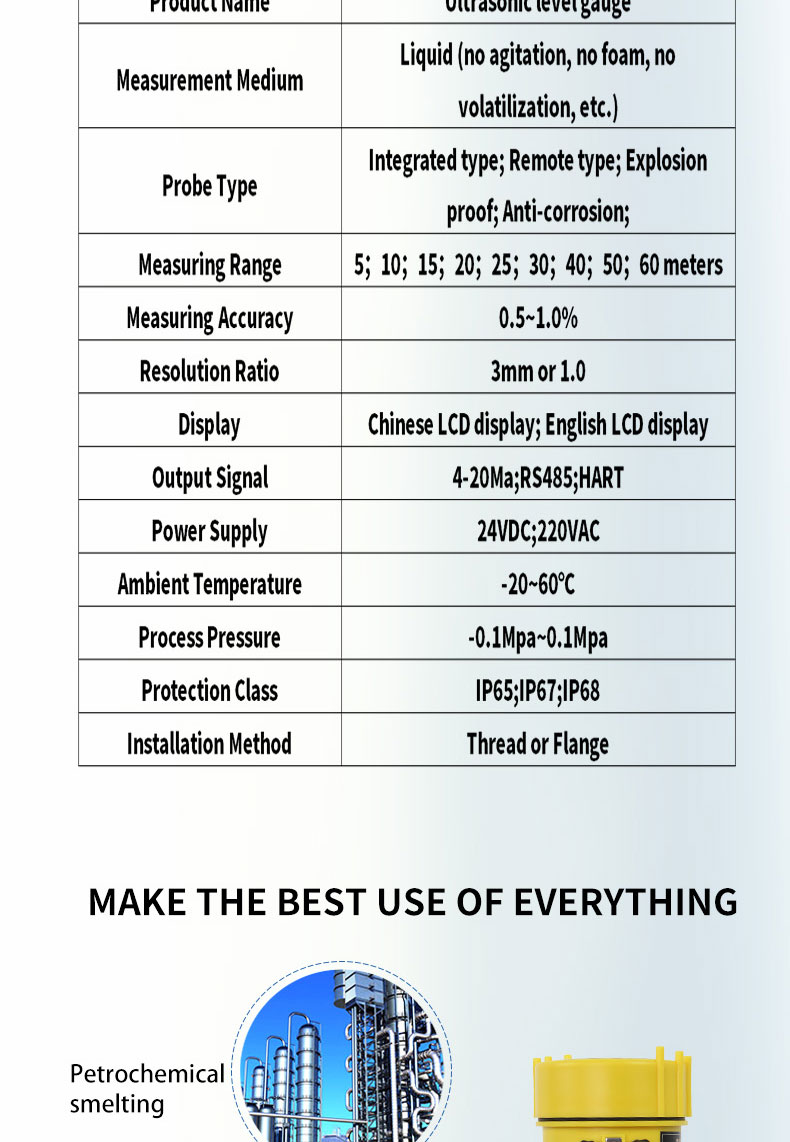

3. There are three ranges to choose from 5 meters, 10 meters, and 15 meters, which can be applied in different industrial environments.

4. High explosion-proof level (ExdIICT6Gb) and protection level (up to IP66/67).

5. The PVDF material probe ensures reliable measurement of the instrument in corrosive liquids or environments.

6. High cost-effectiveness, low maintenance cost, simple structure, and convenient installation.

7. The structure is simple, the reading is convenient, and it is very easy to install and maintain.

8. Safe and clean, long service life of instruments, stable and reliable measurement, and high accuracy.

9. Clear applicability. Although ultrasonic level measurement products are widely used, their measurement principle is based on the propagation speed and time of sound waves in the atmosphere. Therefore, ultrasonic level meters cannot be used for level measurement in closed containers, high-temperature, high-pressure, and other working conditions.