Advantages:

1. Directly measuring mass flow rate without knowing the accurate value of fluid density has high measurement accuracy, which is very advantageous for complex process requirements and measurement of multi-component mixed fluids.

2. It can measure a wide range of fluids. Various liquids include high-viscosity liquids, slurries containing solids, liquids containing trace gases, and medium to high-pressure gases with sufficient density.

3. The vibration amplitude of the measuring tube is small and can be considered as a non-moving part. There are no obstacles or moving parts in the measuring pipeline.

4. Not sensitive to flow velocity distribution, therefore there are no requirements for upstream and downstream straight pipe sections.

5. The Coriolis mass flow meter has high accuracy and stable performance. Within a wide flow range, its measurement accuracy can reach 0.1% to 0.2% and is not affected by factors such as temperature and pressure.

6. Multiple parameter measurements can be made, with the main measurement parameter being mass flow rate. The second measurement parameter is fluid density, with an additional measurement of fluid temperature. It can also be derived from mass flow rate and fluid density to measure the concentration of solutes in two-component solutions.

Features:

- Able to directly measure the mass flow of fluid (this is very important for energy metering and chemical reaction production

- Process detection and control is of great significance);

- High measurement accuracy (measurement accuracy can be guaranteed to be between 0.1% and 0.5%);

- Wide range of applications (in addition to normal fluid measurement, it can also measure general fluids that are difficult to measure.

- Measured industrial media, such as non-Newtonian fluids, various slurries, suspensions, etc.);

- The installation requirements are not high (there are no requirements for upstream and downstream straight pipe sections);

- Reliable operation and low maintenance rate;

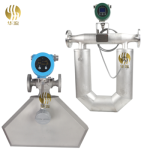

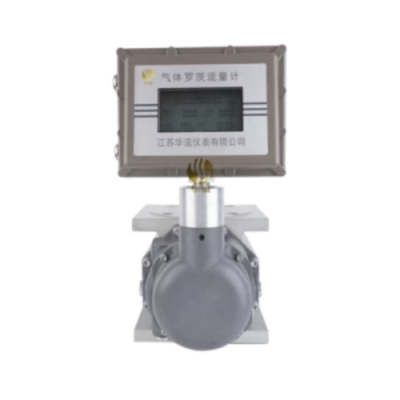

- It consists of a measuring tube, a measuring tube driving device, a position detector supporting structure, a temperature sensor,

- The shell is composed of several parts.